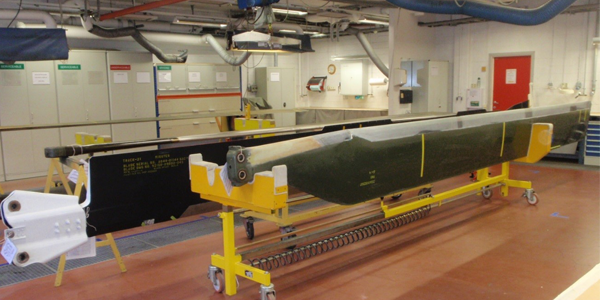

Rotor Blade Repair and Overhaul Capabilities

Heli-One’s Norway facilities has the capability to repair rotor blades for the AS332 L/L1/L2, H225, and AS350. Their state-of-the-art Blade Shop has specialized tooling and resources that facilitates quick repair work. The shop is qualified to for COV (Level I+) and BOV (Level D) work and has been trained by the OEM to perform repairs.

AS332L & L1

- L/L1 Replacement of all, or individual leading edges due to separation/cracks or wear

- Static balancing

- Trim tab repair or replacement

- PU spacing rings replacement

- Paint touch-up

- Modification from 332A11-0024 to 332A11- 0025, and lower surface polyurethane protection replacement

AS332L2

- L2 Replacement of all, or individual leading edges due to separation/cracks or wear

- Static balancing

- Trim tab repair or replacement

- PU spacing rings replacement

- Paint touch-up

- Lower surface polyurethane protection replacement

H225

- Leading edge tip cap replacement

- Trim tab repair or replacement

- Lower surface polyurethane protection replacement

- Repair of PU spacing rings

AS350

- Nickel strip replacement

- Trim tab repair and replacement

- Paint

- Skin damage repair

- Repair of trailing edge damages

- Repair of bonding foil

- Static balancing

- Lower surface polyurethane repair and replacement

Contact Us for Details and Pricing